Manufacturing Services

Mechanical Assembly

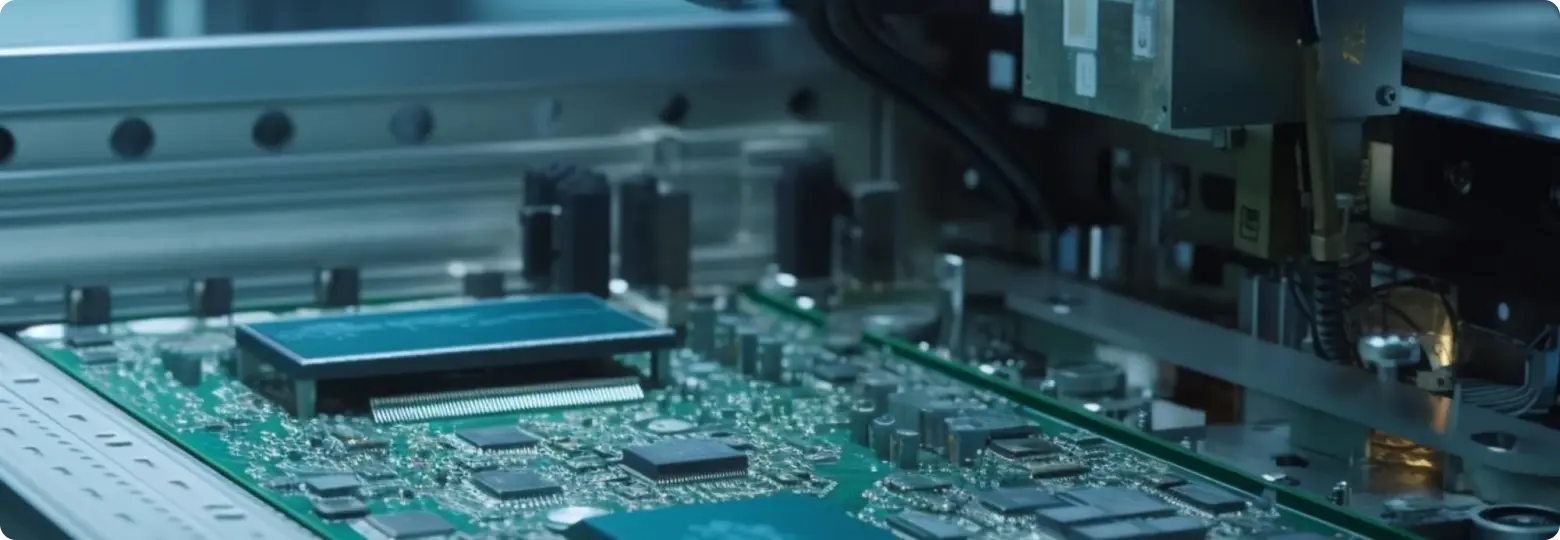

Printed Circuit Board Assembly (PCBA) Services

Printed circuit boards (PCBs) have become crucial cornerstones across diverse industries. We offer a comprehensive selection of PCB assembly services customized to meet your specifications, from prototyping to full-scale production. Our PCB assembly processes include a series of steps from component procurement, SPI, component mounting, soldering, AOI, THT, and conformal coating to inspection and testing.

Partial and Full Turnkey PCB Assembly

Our turnkey services provide comprehensive end-to-end solutions encompassing all aspects of PCB assembling. This streamlined approach offers exceptional convenience for most OEMs, eliminating the need to engage multiple vendors.

We offer part sourcing, assembling, testing, prototyping, and after-sales services, with full or partial turnkey assembly, using surface mount technology (SMT) and through-hole technology (THT).

- Complete turnkey PCB assembly comprises end-to-end solutions, which include everything from material procurement to assembly and dispatch.

- Partial turnkey PCB assembly refers to product assembly according to the design, using at least some customer-provided parts.

We can acquire ball grid array (BGA), uBGA/Micro BGA, chip-scale packaging (CSP), and more. We use lead-free and RoHS-compliant solder types and advanced soldering techniques, such as selective wave soldering, Pb88 soldering, high melting point (HMP) soldering, and Au80 soldering. In addition to manual visual inspection, we offer SPI, microscopic inspection, flying probe test (FPT), AOI, and X-ray inspection, as well as functional and pre-compliance testing.

Board Bring-Up and Diagnostics

We comprehensively validate new circuit board designs, ensuring electrical and functional integrity. With meticulous attention to detail, we address and rectify any pre-existing design flaws and manufacturing process errors, instilling confidence in the hardware’s readiness for the software engineering phase.

Electronics Manufacturing

Conformal Coating

Printed circuit boards (PCBs) are often exposed to various work environments, where they encounter potential hazards such as chemicals, moisture, dust, temperature fluctuations, and vibrations. These elements can significantly impact the performance of PCBs. We offer conformal coating services to mitigate these risks. Our conformal coating options include silicone, acrylic, parylene, epoxy, polyurethane, and thin film/nano coatings.