Both printed circuit boards and printed circuit board assemblies (PCB and PCBA) are parts that are commonly used when crafting electronic devices. At first glance, many people confuse these two terms or use them interchangeably. While both are used within the world of electronics and manufacturing, they serve very distinct functions.

In fact, the difference between PCBs and PCBAs is so distinct that one is not actually functional while the other is. In this article, we’ll dive into the differences between PCB and PCBA, covering everything you need to know about these two foundational electronics parts.

We’ll cover the following:

- What is a PCB?

- What is a PCBA?

- What is the difference between PCB and PCBA?

Let’s dive right in.

What Is a PCB?

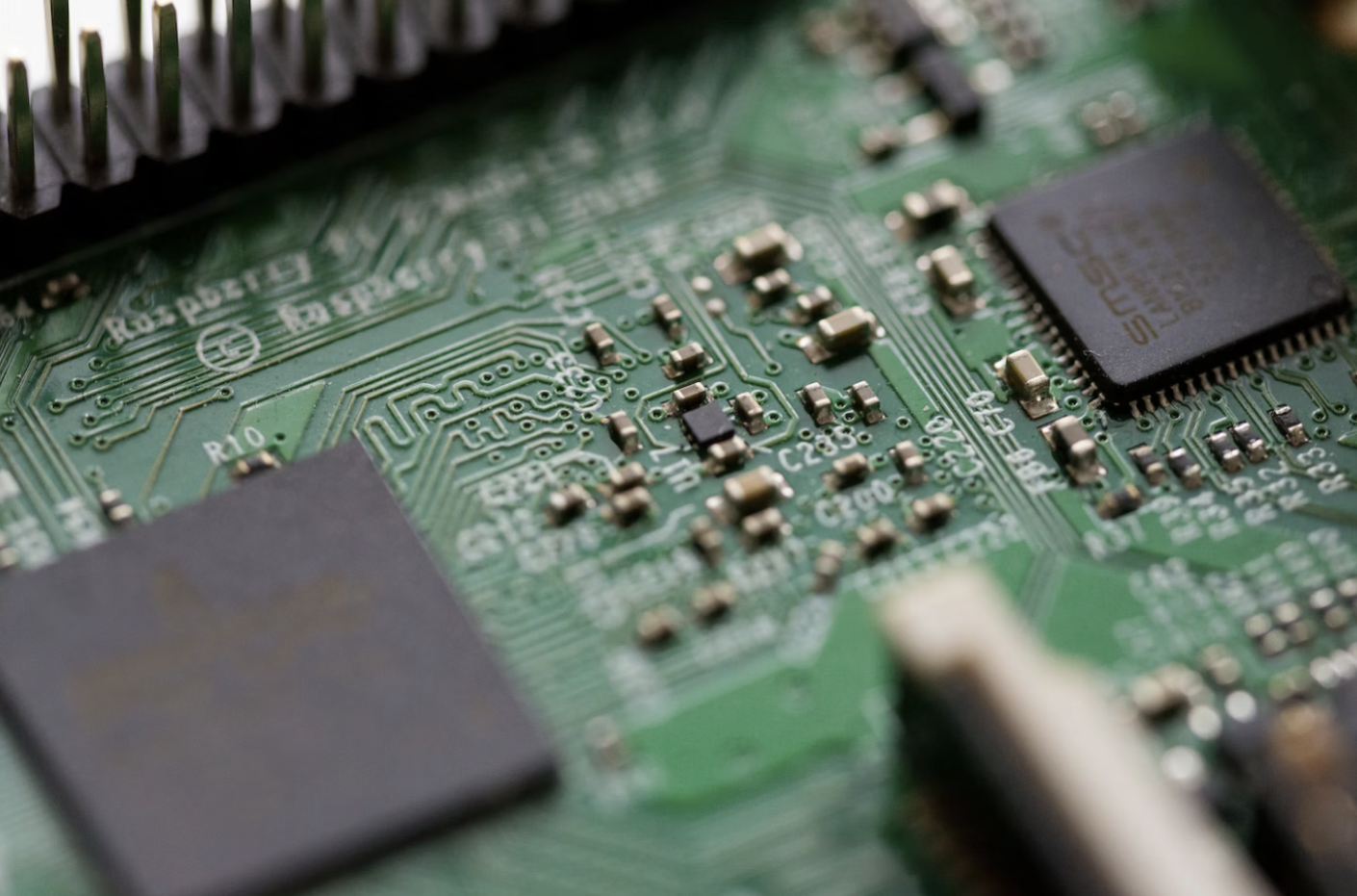

A PCB, also known in its full extent as a printed circuit board, is a building block upon which manufacturers can then build entire electrical systems. They are boards that contain thin layers of conductive copper, allowing electronic components to connect with one another. Most of the time, this layer of conductive material is encased by fiberglass or composite epoxy.

Using a PCB, manufacturers can connect various electronic devices, creating a comprehensive system of connections. As PCBs are so small, they are incredibly efficient, which is one of the main reasons that they’ve been a core part of the majority of consumer electronics.

While you can attach many parts to a PCB, what makes it a PCB and not a PCBA is the fact that it is completely blank to start with. It has everything the board would need to function, but lacks the parts. That’s why it is commonly known as the first building block, rather than a working part in itself.

There are many types of PCBs, with the most common being larger multi-layers, which are used in more complex electrical circuits. However, you can also find single-layer PCBs and double-layer PCBs for more concise applications. That said, the PCB industry is expanding every single day, with new trends like environmentally-friendly PCBs becoming more popular.

What is a PCBA?

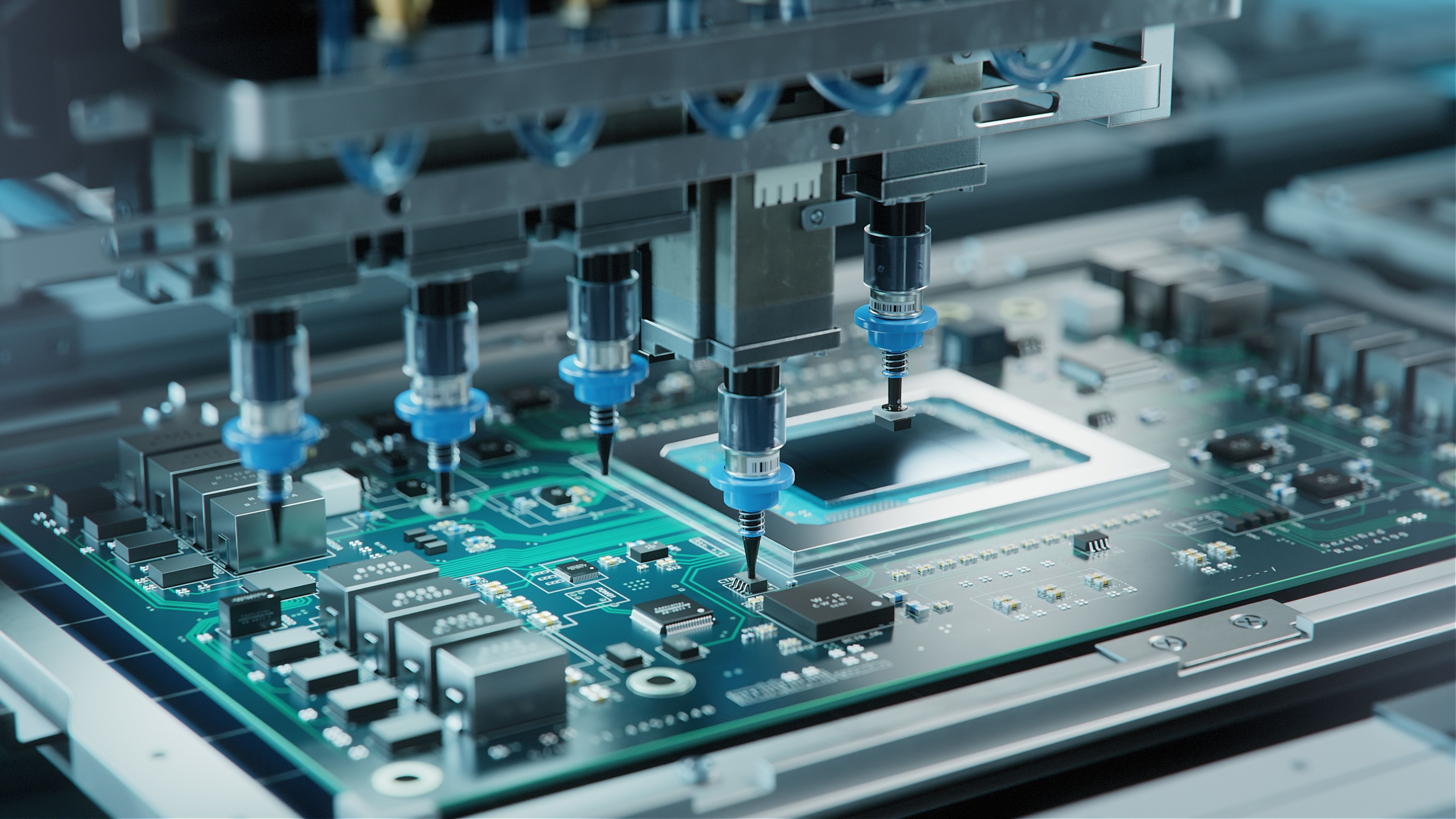

A PCBA builds off the back of a PCB, standing for printed circuit board assembly. The main difference between these two components is that a PCBA also has electronic components on its surface. By soldering different additions, a manufacturer can create a functional circuit board. While this used to be done by hand, the development of this industry has now bestowed a number of machines that will pick and place specific parts onto the board.

At present, PCBAs are used in the vast majority of electronic products. By buying a PCBA instead of a PCB, a manufacturer is able to save time by slotting the already functional circuit into their product. With this in mind, it’s no surprise that you’ll find PCBAs in everything from computers and smartphones to medical technology and even automotive electronics.

While PCBAs may start as blank PCBs, they ensure a high-quality, reliable, and cost-effective way of producing electronic products.

How are PCBAs Made?

As PCBAs are the next step in a PCB’s manufacturing journey, there are now a number of established methods that businesses use to craft them. Out of these methods, there are two that have rapidly become the most popular strategies to use:

- Surface-Mount Technology – SMT is an automated process that allows manufacturers to forge lots of connections on the surface of a PCB at once. Using a pick-and-place machine, a robot will align different pieces with the PCB. From there, the board is heated, melting the solder past and joining those pieces to the board. This produces a fully functional PCBA that’s ready to go.

- Thru-Hole Technology – Before SMT became popular, Thru-Hole was the go-to technology. This process involves the manufacturer drilling holes in a PCB, then using these holes to attach leads to different components, which are then soldered in place.

Thanks to the rapid evolution of the manufacturing industry, using automated technology to produce PCBAs has reduced their cost and allowed for the rise of low-cost electronic devices.

What Is the difference between PCB and PCBA?

While PCBA and PCB technologies are both similar in their initial structure, their final function is fairly distinct. A PCB is used as a building block upon which manufacturers can produce more complicated electronic products. A PCBA, on the other hand, is already made into a certain formation, allowing manufacturers to bestow an electronic product with a certain function.

With this in mind, there are a number of differences between PCB and PCBA tech that we can draw:

- Structure – A printed circuit board is only a board with conductive material inside. A PCBA will have a number of additional parts soldered to it, making it actively usable.

- Purpose – A PCB is inactive, meaning that its purpose is to be given new parts and soldered before being placed into an electronic device. PCBAs, on the other hand, are already soldered and have their functioning parts active.

- Packaging – Most of the time, PCBs will come in vacuum-packed storage. PCBAs are more complicated, often needing anti-static packaging to protect the electronic components inside.

- Process – PCBAs are ready to use, while PCBs must still have parts soldered to them before they are ready to be placed into an electronic device.

While PCBs and PCBAs share similar technology, they represent different steps in the manufacturing process for electronic devices.

Final Thoughts

Both PCBs and PCBAs are useful pieces of technology that each have their place in the world of electronics manufacturing. It can be said that you cannot really have one without the other, as PCBs need parts to function, which would make them PCBAs, and PCBAs need the baseline PCB technology before becoming PCBAs.

While they are similar in many ways, their purpose is ultimately different. If you’re looking for world-class electronics manufacturers, look no further than ELECAAS. With years of experience in this world, we’ve refined the process of creating PCBs and PCBAs, using them to produce our phenomenal range of electronic products.