To-Life and To-Market Development

Product Development

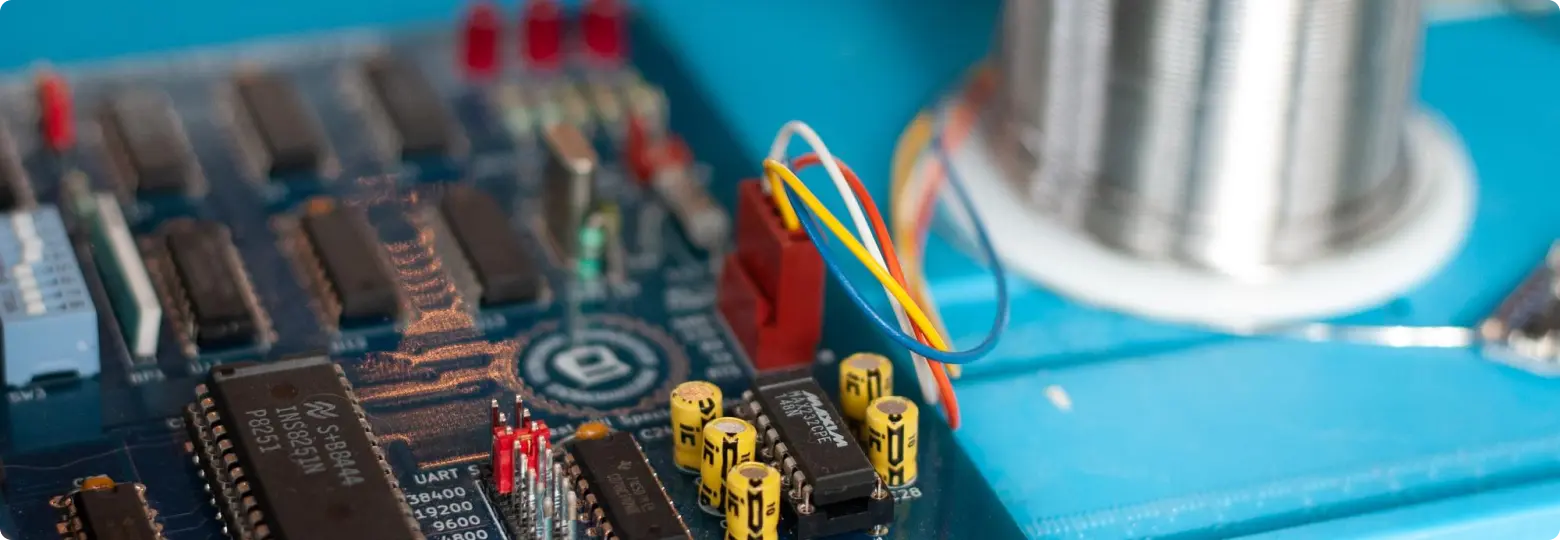

Custom PCB Design and Engineering

Our services encompass custom design and layout of printed circuit boards tailored to your specifics, whether analog, digital, or mixed-signal boards. We offer expertise in creating PCBs from the ground up or refining and enhancing existing designs to ensure cost-effective assembly.

Mechanical Engineering Design

We deliver innovative custom PCB design solutions for electronic devices across diverse industries. We streamline the entire process, facilitating the development of complex mechanical designs and accelerating the time-to-market, ultimately boosting the product’s market penetration.

Embedded System Design and Board Support Packages (BSP) Development

We specialize in delivering robust and dependable embedded system design and firmware development services across a wide range of standard microcontroller and system-on-chip (SoC) platforms. Our offerings span from Linux-based embedded operating systems to bare-metal and Windows environments, catering to both standard and custom-designed systems and boards. With expertise in real-time operating systems (RTOS), Robot Operating Systems (ROS), and non-OS-based firmware development, our team ensures versatile solutions tailored to diverse project requirements

X-Ray Inspection

We offer X-ray inspection technology, a powerful tool for uncovering an object’s hidden features. It is a non-destructive method for assessing PCB quality and detecting hidden defects without risking damage to the board.

Sourcing Electronic Components

We understand the challenges of procuring electronic components. Our extensive global network and rigorous quality control processes ensure we will find a solution. We meticulously inspect every component through established procedures, both in-house and in collaboration with our trusted partners. Our vast inventory across strategically located warehouses also increases the likelihood of having the parts you need readily available for immediate shipment.

Rapid Prototyping

PCB Prototyping and NPI

Creating a PCB prototype before full-scale production allows customers the opportunity to make necessary adjustments and provides them with an accurate representation of the final product. Prototypes offer various benefits, including serving as a reference for future product innovations. This concept aligns with the New Product Introduction (NPI) process, where the prototype of Product A serves as the foundation for developing a new Product B. The NPI process utilizes all manufacturing stages, from ideation and design to testing, implementation, and beyond.

Mechanical Parts 3D Printing

3D printing offers a versatile and adaptable manufacturing process. It is particularly valuable for rapid PCB production and prototyping, custom PCB component creation, and low-volume production runs, and it excels in scenarios that demand fast lead times, cost-effective customization, and complex geometries.

Test Development

Functional Testing

Functional testing ensures the proper functioning of the PCB. Unlike component-level testing, functional tests evaluate the entire assembly. Functional tests replicate the electrical conditions in which the PCB will operate, providing an accurate and comprehensive assessment of its performance.

Pre-Compliance Testing

Pre-compliance testing is a proactive approach that helps assess whether the product aligns with relevant standards before submission to authorized testing programs. This invaluable testing method saves considerable time and resources by mitigating the need for rework later in the process.