1. Your Unique Needs

There are a number of factors you must take into account when selecting a PCB Design and Manufacturing Partner. Here are the six main factors, starting with taking your own unique goals, vision, and needs into account. Does the manufacturer understand your vision?

2. Manufacturing Capabilities

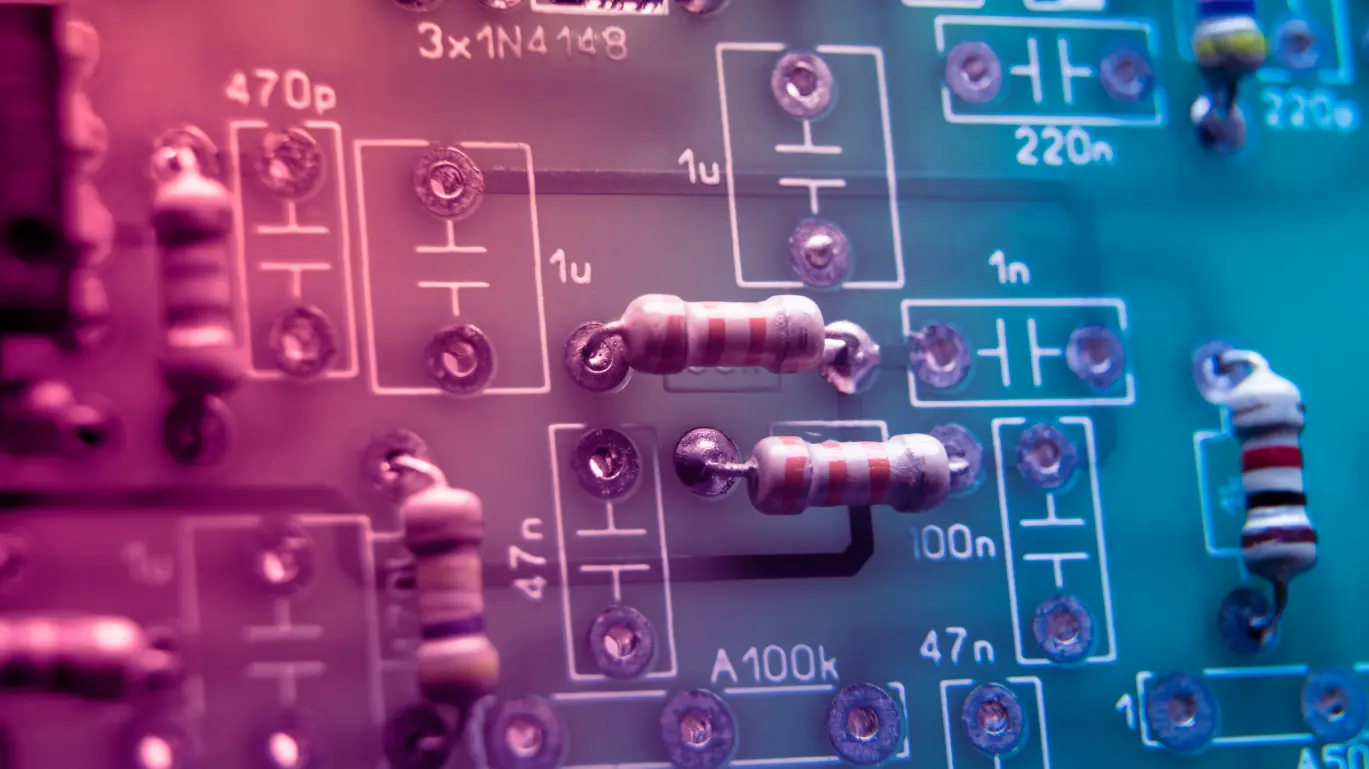

Be sure to ask questions and gather detailed information about a manufacturer’s capabilities; you must be sure they can handle your project and meet your expectations. Look for a manufacturer with experience in boards similar to yours and that has the equipment necessary for your project.

Capabilities that you might look for include multiple conductive layers, how tightly components can be added to the board, options for via types, specific material needs such as high-frequency laminates, and options for specialized finishes. In terms of manufacturing capabilities, EMS companies that have a range of services, from prototyping to production and testing, could be a great one-stop shop option.

3. Quality Standards

Never compromise on quality. A manufacturer’s commitment to quality is crucial and tells you much about their values.

Look for standards compliance certifications and ask about their inspection processes. Companies that adhere to stringent quality standards will readily share details about their company values and their specific certifications.

These standards provide a roadmap for PCB design, fabrication, and assembly, ensuring consistent quality during all stages of production. You should also inquire about their testing processes; do they offer electrical testing, automated optical inspection, or x-ray inspection?

Quality is essential for your project. Otherwise, you might find yourself with an unreliable board that requires reworking and further testing. Knowing that standards are met and quality assurance procedures are in place will offer peace of mind and confidence in your PCB partner.

4. Support And Communication

Establishing effective communication with the PCB manufacturer, especially if your project includes design and prototype stages, is necessary. Be sure the company offers technical support to help troubleshoot and optimize your design and respond to issues quickly as they arise.

Clear and consistent communication provides the foundation for a successful partnership with your manufacturer. A company that offers effective communication will often have a point of contact who will keep you updated on your project’s progress and respond to your questions and concerns during the process.

Strong communication can help you stay in control of your project and make informed decisions at each step. Even the best plans sometimes require adjustments, and with open lines of communication, these adjustments or changes can be made smoothly and collaboratively.

5. Value

Value is undoubtedly an essential factor, often at the top of the considerations list. Choosing the highest quality possible while staying within your budget certainly impacts your choice of manufacturer.

Look for clearly outlined pricing structures without hidden fees. Value incorporates several factors in addition to the proposed quote or total cost of the project.

Consider the overall value, including product quality, company support, and reliability, not only the price of the services you choose. The best value can be found in a company that provides exceptional quality, outstanding service, and offers competitive pricing.

A successful partner understands the relationship between quality, cost, and timely delivery and is dedicated to your project, from design concepts to completed production.

6. Turnaround Time

The turnaround time is the time between placing your order and receiving the finished product. This time frame can impact your project’s timeline and should be considered a factor in choosing a partner.

Look for a manufacturer with a turnaround time that aligns with your needs. Whether prototyping a new design or increasing production of a completed design, delays or really any misalignment of the timeline can derail your entire project and cause headaches.

Factors such as PCB complexity, order volume, and specific manufacturing needs can influence turnaround times. Be sure to discuss your project timeline and requirements openly and upfront with potential partners to make sure they can meet your expectations.

The Final Decision

Choosing the right PCB manufacturer for your project is a critical step in the process. It comes down to finding the best fit and the right partner for your project. Once you understand your needs, you can seek out potential partners and weigh the factors that impact a balanced and successful partnership.

By prioritizing your project’s specific needs, from complexity and budget to turnaround time and certifications, you can narrow down your search to qualified options. Remember, capability is just the starting point.

Look for a partner with experience in your industry, a commitment to clear communication, and expertise in design, prototyping, or any specialized requirements you have. A robust quality control process and a focus on meeting your needs are essential.

Don’t hesitate to ask questions and establish open communication – a strong partnership is vital for success. With careful consideration and collaboration, you can find the perfect PCB manufacturing partner to translate your vision into a reliable, high-quality product, propelling your project to the next level.

Remember, the ideal partner isn’t just a manufacturer but an invested collaborator. At Elecaas, we pride ourselves on becoming an extension of your team and meeting your unique needs.

Visit www.elecaas.com to explore how we can help.